Factory making Good Welding High Test 6mm/8mm/10mm Electro-Galvanized Fenderr Chain with Good Usage Feedback

Sticking for the principle of “Super Quality, Satisfactory service” ,We have been striving for being a superb small business partner of you for Factory making Good Welding High Test 6mm/8mm/10mm Electro-Galvanized Fenderr Chain with Good Usage Feedback, We’re searching forward to forming prosperous organization marriage with new shoppers during the around long run!

Sticking for the principle of “Super Quality, Satisfactory service” ,We have been striving for being a superb small business partner of you for China Railing Link Chain and Chain, Our Company has specialist engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, You should feel free to contact us.

Product composition

Load binder is a tool used to hold cargo in place and prevent it from moving during transit.It is composed of several key components, these components work together to create tension and fixed the goods in the proper position.

Screw is a kind of threaded rod, handle the rotation, to produce adhesive chain tension loading. The screw is attached to the gear, which rotates as the handle turns, increasing the tension on the chain.

The locking pin is a safety feature that prevents the load binder from accidentally releasing tension. It is inserted into the hole in the gear to lock the screw in place.

The chain ring is the point that connects the load clip chain. It is usually located at the end of the load adhesive opposite the handle.

And Handle is used to turn the screws, creating tension in the chain. It is usually made of steel or other durable material to withstand the force required to tighten the loaded adhesive.

More, Gear is an important part of the loading binder because it allows the screw to rotate and increases tension on the chain. It is usually made of steel and is designed to withstand the forces generated by the loaded adhesive.

In European standard load binders, the wing hooks are used to connect the load binder to the load and are designed with a wing-shaped profile to prevent slippage. The safety pins are used to secure the wing hooks in place and prevent them from becoming dislodged during transport. Load binder is a simple but effective tool that is used to secure cargo during transport. Its various parts work together to create tension on the load binder chain, ensuring that the cargo remains securely in place until it reaches its destination. Proper use and maintenance of the load binder and its parts are important to ensure safe and effective cargo transportation.

Matched Transport Binder Chain

G70 CHAIN NACM1996/2003 STANDARD LINK CHAIN

Code No. Chain assemblies with Clevis Hooks

G7C8-165/16-in.x16-ft. Working Load Limit:4,700lbs. Weight:17.40lbs./7.89kg

G7C8-205/16-in.x20-ft.Working Load Limit:4,700lbs. Weight:21.70lbs./9.90kg

G7C8-255/16-in.x25-ft.Working Load Limit:4,700lbs.Weight:26.70lbs./8.07kg

G7C10-163/8-in.x16-ft.Working Load Limit:6,600lbs Weight:17.80lbs./10.10kg

G7C10-203/8-in.x20-ft.Working Load Limit:6,600lbs Weight:22.20lbs./7.89kg.

G7C10-253/8-in.x25-ft.Working Load Limit:6,600lbs Weight:27.20lbs./12.40kg

G7C13-201/2-inx20-ft. Working Load Limit:11,300lbs Weight:53.60lbs./24.30kg

G7C13-251/2-in.x25-ft.Working Load Limit:11,300bs Weight:66.20lbs./30.01kg

Code No.Chain assemblies with Clevis Hooks

G4C6-201/4-in.x20-ft. Working Load Limit:2,600lbs. Weight:13.50lbs./6.13kg

G4C8-205/16-in.x20-ft.Working Load Limit:3,900lbs.Weight:22.00lbs./9.97kg

G4C10-203/8-in.x20-ft,Working Load Limit:5,400lbs.Weight:31.40lbs./14.24kg

SPECIFICATIONS

| Code NO. | 规格 Min-Max Chain Size (in.) |

工作负荷 Working Load Limit (lbs.) |

测试拉力 Proof Load (lbs.) |

破断负荷 Minimum Ultmate Strength (lbs.) |

重量 Weight Each (lbs.) |

手柄长度 Handle Length (in.) |

螺套长度 Barrel Length (in.) |

收缩距 Take Up (in.) |

| RB1456 | 1/4-5/16 | 2200 | 4400 | 7800 | 3.52 | 7.16 | 6.3 | 4.65 |

| RB5638 | 5/16-3/8 | 5400 | 10800 | 19000 | 10.5 | 13.42 | 9.92 | 8 |

| RB3812 | 3/8-1/2 | 9200 | 18400 | 33000 | 12.2 | 13.92 | 9.92 | 8 |

| RB1258 | 1/2-5/8 | 13000 | 26000 | 46000 | 14.38 | 13.92 | 9.92 | 8 |

| RB*5638 | *5/16-3/8 | 6600 | 13200 | 26000 | 11 | 13.42 | 9.92 | 8 |

| RB*3812 | 3/8-1/2 | 12000 | 24000 | 36000 | 13.8 | 13.42 | 9.92 | 8.2 |

Heavy Duty Hook

The forged grab hook can swivel 360° and engage easily with the chain. Suitable for most locks.

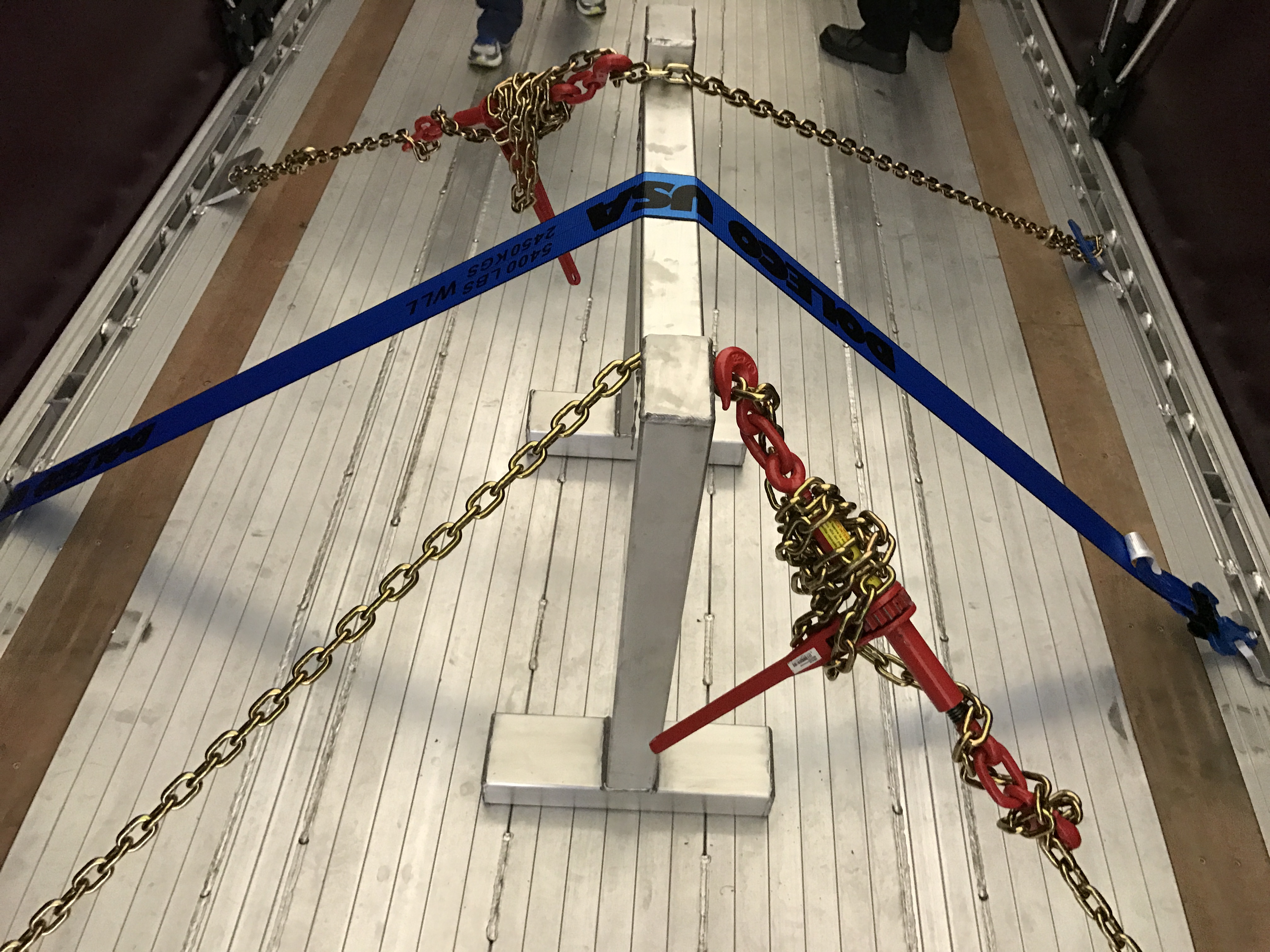

Easy to use by chain and Hook

Smooth ratcheting gear and pawl design tighten the chain to secure the load faster.

Widely Usage

For most industrial applications such as factories, warehouses, garages, docks, etc., they are ideal for securing, logging, securing and towing goods.

Adjustable range

This product has a very long adjustable range, you can control its length in your different use scenarios, each style has a different size specification

Steel Material

The ratchet load binder is made of heavy-duty steel with a powder coat finish that resists wear and rust is built to last. And the chain is made of 20Mn2 material with G70 hooks.

High security

Our load binder provides a load-bearing binder for almost all industries, with rigorous testing standards. And has the anti-runaway device, to prevent accidents in the process of use.

The Production Process of Load Binder

Raw Material Preparation:

The first step is to procure the raw materials required

for the production of load binders. The primary raw

materials used in load binders are high-quality steel,

such as carbon steel and alloy steel.

Cutting and Shaping:

The steel is then cut and shaped into the required size and shape using specialized equipment like saws, presses, and drills.

Forging:

Through the electric furnace heating, the handle through the abrasive molding, the second forging press on the product typing.The shaped steel is then heated and forged into the desired shape using a hydraulic press. This process helps to improve the strength and durability of the load binder.

Finish machining:

After forging, Finishing is mainly processing ratchet binder screw sleeve and screw, through CNC machine tool processing screw sleeve and screw grain. This process is essential to ensure the load binder can perform its intended function effectively.

Saw groove and Drill:

Slots on ratchet and lever load binder handles are cut by machine wire.

Through machine processing, the holes for subsequent installation are processed,

mainly processing handles, and the holes for installing safety pins with wing hooks

Heat Treatment:

Load binders undergo heat treatment to improve their strength, hardness, and durability. The steel is heated to a specific temperature and then cooled down slowly to create the desired properties.

Welding:

Weld the finished hook chain ring to the screw of the load binder.

Assembly:

The different components like the handle, gear, screw,

and lock pin are assembled to create a functional load binder.

Surface Treatment:

After heat treatment, the load binders are treated to prevent rust and corrosion.

Surface treatments like electroplating, powder coating, or painting are applied

to the load binder to enhance its appearance and prevent rusting.

Package:

Oil the screw of ratchet load binder, install the safety pin on the

wing hook, hang the warning tag, put on the plastic bag, pack and pack

Quality Control:

Before the load binder is released into the market, it undergoes

quality control checks to ensure that it meets the required standards

and specifications. This involves testing the load binder’s strength,

durability, and ability to handle the maximum rated load.

Use of Load Binder

Before using the load binder, ensure that the chain is in good condition and free from any damage or defects.

•Attach the load binder to the chain by inserting one end of the chain into the chain ring and securing it with the lock pin.

•Place the load binder in position over the load.

•Hook the opposite end of the chain to the load.

•Turn the handle of the load binder in a clockwise direction to take up slack in the chain.

•Tighten the load binder until the chain is securely tensioned around the load.

•Once the load binder is tightened, secure it with a safety pin or clip to prevent the handle from turning and the chain from loosening.

•Inspect the load and the load binder regularly during transport to ensure that the load remains secure.

It’s important to note that over-tightening a load binder can damage the chain or the load. Therefore, it’s essential to know the weight and capacity of the load,

and use the appropriate load binder with the correct working load limit (WLL). Also, make sure to follow the manufacturer’s

instructions and any applicable safety regulations or guidelines when using a load binder.

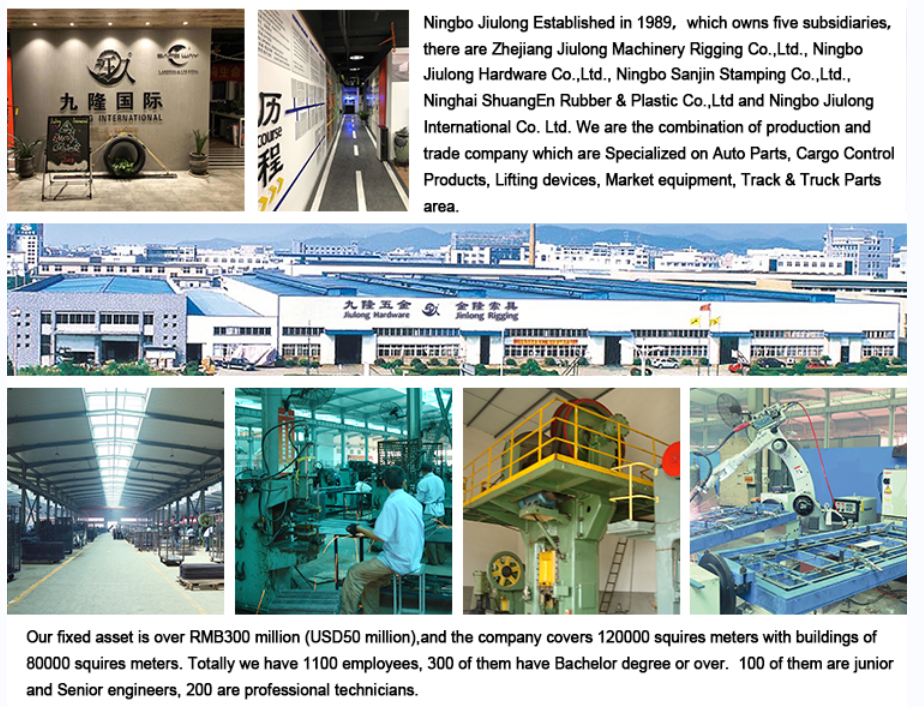

About Jiulong’s after-sales service

At Jiulong, we take pride in not only providing high-quality load binder but also offering exceptional after-sales service to our customers. We understand that unexpected issues can arise during the use of our products, which is why we are committed to providing timely and efficient solutions to any problems our customers may encounter.

Our dedicated customer service team is available to assist with any inquiries or issues you may have with your load binder purchase. We offer comprehensive product support, including guidance on proper installation, maintenance, and troubleshooting. Our team is knowledgeable and experienced, and we are committed to ensuring that our customers have a positive experience with our products.

In addition to our customer service team, we also offer a warranty on all of our load binder. Our warranty covers any defects in material or workmanship and provides peace of mind to our customers. If you encounter any issues with your load binder during the warranty period, we will repair or replace it free of charge. We strive to provide the best possible service to our customers. We are confident in the quality and reliability of our load binder, and we stand behind our products with exceptional after-sales service.

Sticking for the principle of “Super Quality, Satisfactory service” ,We have been striving for being a superb small business partner of you for Factory making Good Welding High Test 6mm/8mm/10mm Electro-Galvanized Fenderr Chain with Good Usage Feedback, We’re searching forward to forming prosperous organization marriage with new shoppers during the around long run!

Factory making China Railing Link Chain and Chain, Our Company has specialist engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, You should feel free to contact us.